Our adventure

Cooll’s adventure started at the University of Twente back in 2003, when a vibration-free cooler for temperatures up to -270 ºC was developed for the ESA aerospace program. The carbon-ammonia adsorption technology used for this cooler formed the basis for the heat pump technology of Cooll. In 2008 the research into sustainable heating and cooling based on adsorption technology was started, resulting in the founding of Cooll in 2009.

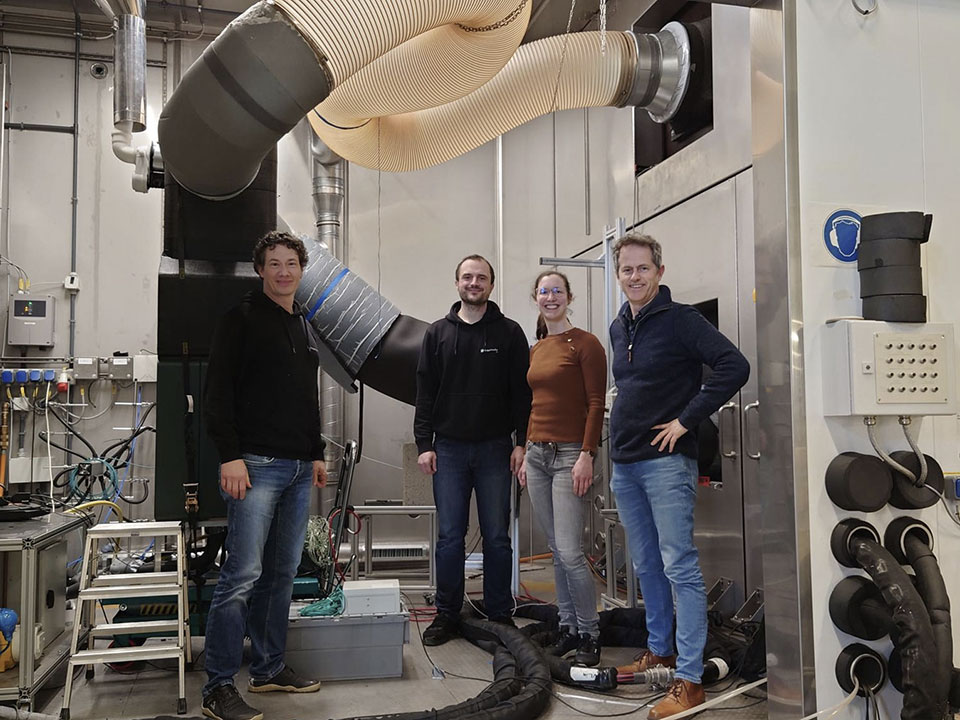

The first wall-mounted functional model was realized in 2018 and has been used to heat the office of Cooll for two subsequent years. A similar, transportable, heat pump system was developed to facilitate external testing. The first demonstration in a representative, but unhabituated, Dutch house with this unit took place in 2020. The first field test certified unit was installed in a habituated social corporation house in 2022.

In parallel, Cooll has proven the reliability of the latest design of its proprietary core technology components with Accelerated Life Testing (ALT) and has realized a prototype production facility to produce the core technology components needed for field tests and Joint Development programs.

Cooll’s latest product prototype, FP1, was designed according to all the necessary European safety regulations and standards, resulting in the Kiwa certificate that was obtained in December 2023. In March 2024, the first FP1 unit was installed in the Green Village fieldlab for Sustainable Innovation in Delft. In April 2024, FP1 was tested against the EN 12309 performance standard at Fraunhofer ISE, resulting in a provisional energy label A+. Based on this evidence, Cooll is now preparing for commercial roll-out of the technology, by seeking partnerships with HVAC producers in the United States, Asia and Europe.