Technology

Our thermally driven heat pump is a one-on-one replacement for the condensing boiler in existing homes. It can be combined with both high- and low-temperature heating and does not have a separate outdoor unit. It is powered by natural gas, biogas or hydrogen and extracts heat from the outside air, achieving a reduction on gas usage and CO2 emissions of 30 to 40%. All without a significant increase in electricity consumption.

Functioning

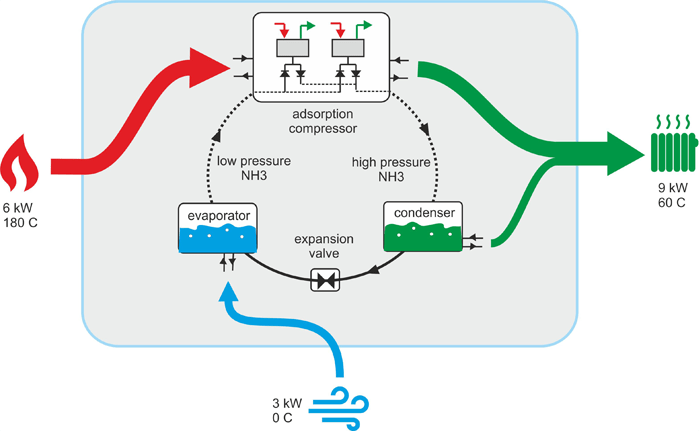

Cooll’s adsorption heat pump has a similar refrigerant cycle as a standard electric heat pump. However, compression of the refrigerant does not takes place with a mechanical compressor, but the cycle is driven by an adsorption compressor instead. This adsorption compressor requires heat and cold instead of electrical power and the system is therefore a Thermally Driven Heat Pump (TDHP).

The adsorption compressor consists of two pressure vessels filled with high-quality activated carbon, that are heated and cooled subsequently. During the heating phase, the refrigerant is desorbed out of the adsorbent material under high pressure and is directed to the high-pressure side of the heat pump. The refrigerant transfers its heat to the heating circuit of the house in the condenser, after which the pressure of the refrigerant is reduced via the expansion valve. The refrigerant then evaporates at the lower pressure and temperature in the evaporator and thereby extracts energy from the outside air. After evaporation, the refrigerant flows back to the pressure vessel that is cooled, where the refrigerant adsorbs to the adsorbent material. After about 5 minutes, the function of the two pressure vessels is reversed, wherewith a continuous process is created. Compared to a standard combustion boiler, the efficiency gain is realized by the heat that is extracted from the outside air in the evaporator and added to the heating circuit in the condenser.

Innovations

The benefits of our technology are the result of the integration of several innovations, which have been systematically developed by Cooll and its partners since 2010:

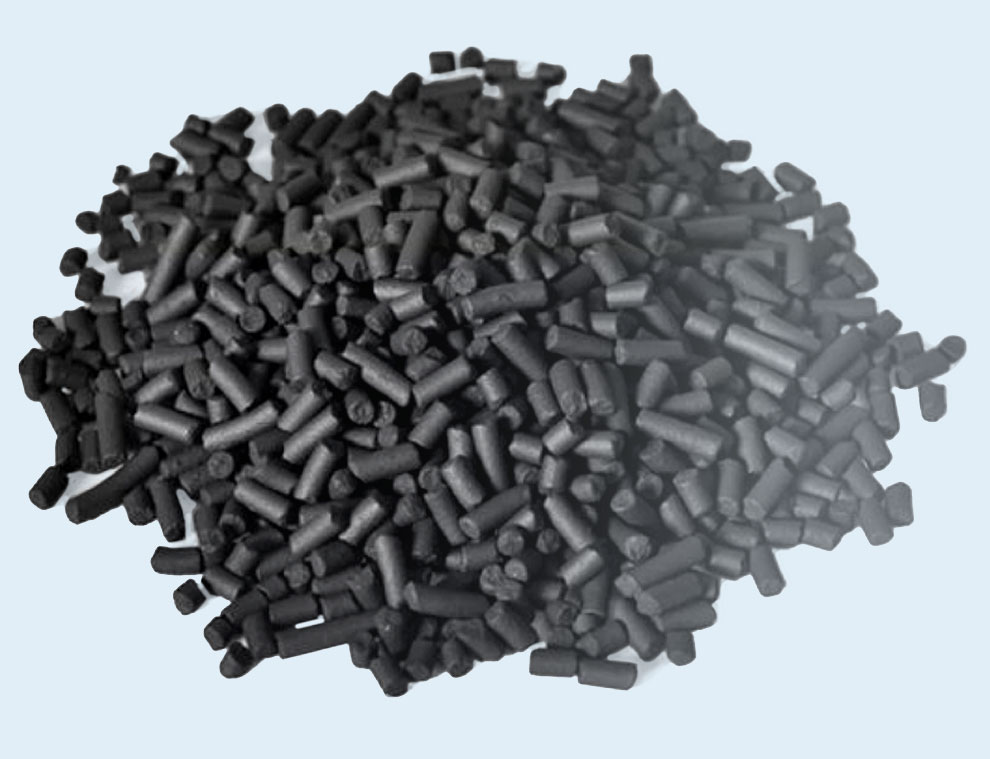

- Carbon-ammonia adsorption cycle with thermal wave heat recovery within the adsorption compressor. This results in a very high efficiency of the compressor;

- Unique design of the two adsorption vessels optimised for the functioning of the thermal wave heat recovery. In addition, the compressor design has been optimized for maximum energy density and minimal dimensions. This is incredibly important for application in a consumer product with compact dimensions.

- High-quality activated carbon, fully optimised for usage in our technology. Together with the design of the adsorption compressor, this forms the heart of the technology.

Benefits

Cooll’s patented technology results in a number of important benefits compared to similar techniques:

1. Energy reduction of 30-40%

Reduction of 30-40% or the required energy and associated CO2 emissions, compared to traditional gas-fired heating technologies.

2. Replacement of condensing boiler

The core technology allows for a heat pump that is compact, quiet, easy to install and that needs little maintenance. This makes the heat pump ideally suited as replacement for the condensing boiler in existing homes. With the energy savings achieved each month, competitive costs of ownership can be realized without any loss in comfort. An improved energy label rating can thus be realized in an easy and affordable way.

3. Well suited for sustainable energy carriers

Next to natural gas, other gases can be used in the heat pump technology to create thermal energy to drive the compressor. The advantage of these energy carriers (compared to green electricity) is that they can be stored on a seasonal basis, for use in colder periods. The high efficiency of Cooll’s technology enables both a cost effective and a more efficient energy system based on carbon free gases and seasonal storage.

Applications

Our TDHP technology can be used with different fuels, heat sources and delivery systems.

Fuel

In principle all combustible energy carriers, either gas, liquid or solid can be used with Cooll’s technology. Only the combustion chain needs specific, fuel type, adjustments, as is the case with traditional boilers.

Heat Source

Similar to other heat pumps, different sources can be used to extract heat from. As default, Cooll’s heat pump works with the outside air as heat source, where it has the advantage that the compact evaporator is part of the inside installation and does not require an outside unit. Other system configuration using nearby sources of water, ground geothermal energy or even waste heat are also possible with Cooll’s TDHP.

Delivery circuit

Here, a distinction can be made between:

- High-temperature heating systems (HT), often the case in existing houses.

- Low-temperature central heating (LT). Typically underfloor heating, usually in new built or renovated houses.

As with other heat pumps, the highest savings are achieved in combination with LT systems. However, unlike with electric heat pumps, the energy savings remain relatively high for HT systems. This makes the technology very suitable for existing homes with high temperature central heating.

Commercialization

After successful demonstrations in a several Dutch households since 2020, Cooll is now preparing commercial market introduction with partners. In 2024 Cooll will demonstrate the maturity of the technology with its latest certified product prototype, FP1, in a couple of test locations. In the meantime, the heat pump is also prepared to work on 100% hydrogen.